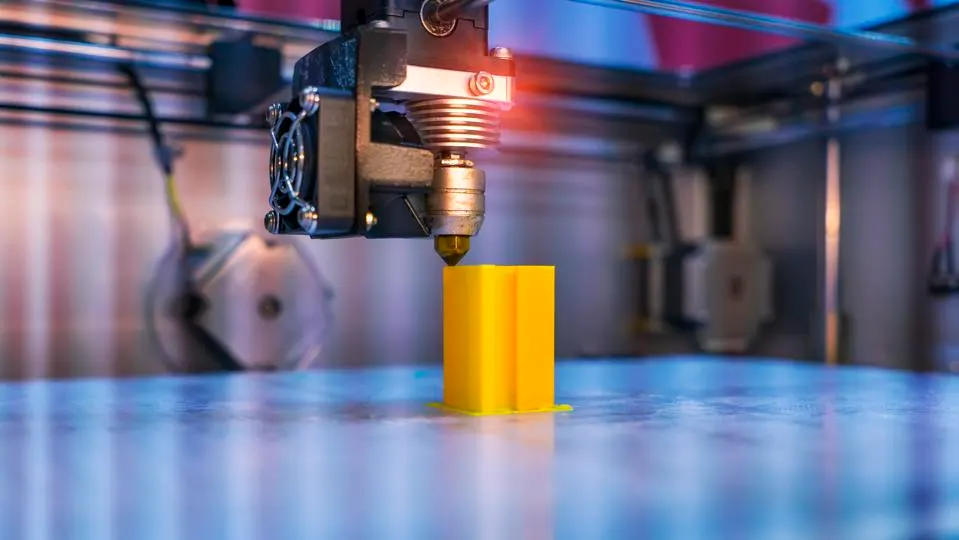

The automotive industry is characterized by its constant pursuit of innovation, efficiency, and customization. As consumer demands evolve and environmental regulations become more stringent, the industry is increasingly turning to advanced manufacturing technologies to stay competitive. Among these technologies, commercial 3D printing services stand out as a game-changer, offering new possibilities in design, production, and supply chain management. This article explores how 3D printing is transforming the automotive sector.

Design Freedom and Prototyping

One of the most significant advantages of 3D printing in the automotive industry is the freedom it offers in design. Traditional manufacturing methods often impose limitations on the shapes and structures that can be produced, leading to compromises in design and functionality. In contrast, 3D printing allows for the creation of complex geometries and intricate details that would be impossible or prohibitively expensive to achieve with conventional techniques.

This design freedom is particularly valuable during the prototyping phase of automotive development. Engineers and designers can quickly produce and test multiple iterations of a component, refining designs based on real-world performance data. This rapid prototyping capability accelerates the development process, allowing automakers to bring new models and features to market faster.

Customization and Personalization

The demand for customized vehicles is growing, with consumers seeking options that reflect their personal tastes and lifestyles. Commercial 3D printing services enable automakers to offer a higher degree of customization, from personalized interior components to bespoke exterior details. This ability to tailor products to individual preferences not only enhances customer satisfaction but also provides a competitive edge in a crowded market.

For instance, 3D printing can be used to create custom dashboards, gear knobs, and other interior elements that match a customer’s specific design preferences. Additionally, exterior components like grilles, badges, and trim pieces can be customized to give vehicles a unique appearance. This level of personalization is difficult to achieve with traditional manufacturing methods, making 3D printing an attractive option for automakers looking to differentiate their products.

Reducing Costs and Waste

Cost reduction is a critical factor in the highly competitive automotive industry. Commercial 3D printing services offer significant cost advantages by reducing the need for expensive tooling and minimizing material waste. Traditional manufacturing processes often require the creation of molds and dies, which can be costly and time-consuming to produce. In contrast, 3D printing eliminates the need for these tools, allowing parts to be produced directly from digital designs.

Moreover, commercial 3d printing services is an additive process, meaning that material is only added where it is needed. This approach minimizes waste, as there is no need to cut away excess material as in subtractive manufacturing methods. The result is a more sustainable production process that reduces both material costs and environmental impact.

Streamlining Supply Chains

The automotive industry relies on complex global supply chains to deliver parts and components to assembly plants around the world. However, disruptions in these supply chains, such as those caused by natural disasters or geopolitical events, can lead to costly delays and production stoppages. Commercial 3D printing services offer a solution by enabling on-demand production of parts, reducing dependence on distant suppliers.

By integrating 3D printing into their supply chains, automakers can produce components locally, closer to their assembly plants. This approach not only reduces lead times and transportation costs but also enhances supply chain resilience by minimizing the risk of disruptions. Additionally, 3D printing allows for the production of low-volume or obsolete parts, ensuring that spare parts are readily available even for older vehicle models.

Conclusion

Commercial 3D printing services are transforming the automotive industry by offering new possibilities in design, customization, cost reduction, and supply chain management. As the technology continues to evolve, its impact on the industry is expected to grow, providing automakers with the tools they need to innovate and stay competitive. From rapid prototyping to on-demand production, 3D printing is driving the future of automotive manufacturing.